Everyone is concerned about reducing energy consumption, being smarter about how we use energy, and saving money on energy bills. Buildings with multiple HVAC units have particular issues—running independently all the units can turn on at the same time and cause huge spikes in energy demand. With buildings where the occupants are not paying directly for their energy such as schools, hotels, and Senior Living facilities the users have no incentive to reduce energy consumption, and may may leave their HVAC system at extreme settings when the room is unoccupied for long periods of time. And aging HVAC units can become much less efficient before they fail, and when they fail it becomes a high priority event to repair them.

Centralized control of multiple HVAC systems is a good solution to these scenarios, but it is expensive and sometimes nearly impossible to rewire existing multi-user dwellings to install the centralized controls. Vortechs Automation designs and installs custom control systems for the Green Energy market, and came to MSRK Design with this problem.

Researching the problem:

The first step to a solution is fully understanding the problem–what are the key issues to be resolved, what is the environment of operation, who will be installing and maintaining the system and what is their level of technical interest/understanding, and what are the limitations of the existing solutions. We worked closely with the president of Vortechs Automation, Walter Horigan, to answer these questions and define a product that would meet the needs of this market.

Defining the Product Architecture:

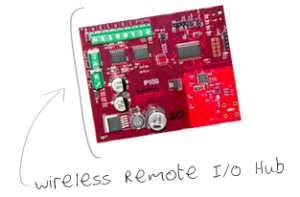

Once we understood the product requirements, we developed the architecture for an RF system with two elements–an RF Node that mounts inside each HVAC housing with 8 inputs, 8 outputs and an RF data link, and an RF Hub mounted in the hallway that bridges the building’s Modbus control network to the Nodes via the RF data link. The Nodes and Hubs needed to be simple to install, robust to handle power surges and faulty installations, and easy to configure. Breadboards of the RF data link system by Cypress Semiconductor were tested at an actual customer site to verify sufficient RF coverage for the system.

Designing the Products:

Vortechs Automation has no electronics engineering staff in-house, so MSRK Design developed the schematics, designed the custom PC Boards, selected and ordered all the components for the production build. Then we selected and worked with a local Contract Manufacturer to assemble the units. Custom antennas were developed to meet the unique requirements of the Node and Hub. Custom firmware was written for the Hub to translate Modbus commands to interface to the I/O on the Node. And custom firmware was written for the Node to address the unique requirements of controlling HVAC equipment, such as short-cycle and power brownout protection.

The Results:

The finished products successfully extend the Modbus control system over 600 feet line-of-site, with a robust RF data link that automatically selects the best operating frequency and data rate to optimize performance. And Vortechs Automation is now pursuing variations of these products for industrial control projects that will only need changes to the firmware to meet particular customer needs.