Pivitec is a cutting edge developer of high-end audio equipment for the professional and commercial audio industry. They developed a product line of multichannel Input and Mixer modules that communicate using the new Ethernet AVB standard. Some of the challenges in their designs are co-locating sensitive audio signals on the same board as high-speed Ethernet signals, and meeting the stringent FCC emissions standards when connecting to the Ethernet AVB network. Their desire was to meet the difficult Class B FCC emissions standard, but their first design was failing even the more relaxed Class A standards that can be used for ‘commercial installations only.’ They came to MSRK Design for help in meeting this goal on their next design pass, which was scheduled to be released the next week.

Identifying the problems:

Pivitec provided the results of the FCC tests done on their prior design, along with the schematics and pcb layout files for the new design about to be built. We reviewed both and determined that there were major issues with the clock signals used for the analog-to-digital converters, and some minor issues with the logic clocks. In addition, the Ethernet circuitry and layout needed some improvements to control the undesired emissions, and the DC power distribution was contributing to the problem. Some circuitry needed to be changed, and the basic architecture of the pcb layout needed to be redone.

Resolving the problems:

Pivitec had their own schematic and pcb layout resources that they wanted to use; MSRK Design was asked to act as an advisor to their team. We scrubbed their schematics and pcb layouts for both products, and provided them with a long, detailed list of specific changes that needed to be made. Several followup teleconferences were held with their team to clarify and modify the solutions. Significant changes were made to the clock distribution circuitry to both control the harmonic frequencies generated, and to facilitate a clean pcb layout to minimize coupling between signals. And the overall pcb architecture was redone to both control the radiated emissions and reduce the coupling between the logic and audio circuitry. The resulting design maintained their low cost 4-layer pcb, and had only a slight increase in component cost.

After Pivitec made the changes to the schematics and pcb design, they sent us the files for review. The new design was much better, but we prepared another list of changes to make before releasing the boards to manufacturing. These changes involved specific runners, bypass capacitors, and their Chassis Ground. A few more followup calls and emails clarified our suggestions.

The Results:

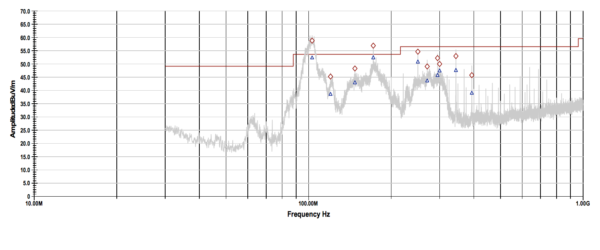

Pivitec had the products built, and then sent them to BEC, one of our recommended partners for EMC testing. The products passed the stringent FCC Class B emissions tests, and also the European CISPR 22 Class B tests! And despite all the board changes to improve radiated emissions, the high quality audio performance was maintained.

According to John Fenley, VP of Engineering at Pivitec, achieving Class B certification opened up their markets significantly–”MSRK was a big key to our success. There is no way I would have been able to get these designs to pass Class B by myself in such a short time…maybe never. Certainly, multiple board revs would have been required. And as a startup, that is something we could not afford. The fact that we did it in one pass is a testament to MSRK’s experience in this area. Plus, you guys are great to work with!”